Accurately measure product fragility and evaluate their response to specific shock inputs. Shock test data is key to determining if your product is capable of withstanding its intended distribution and end-use environment.

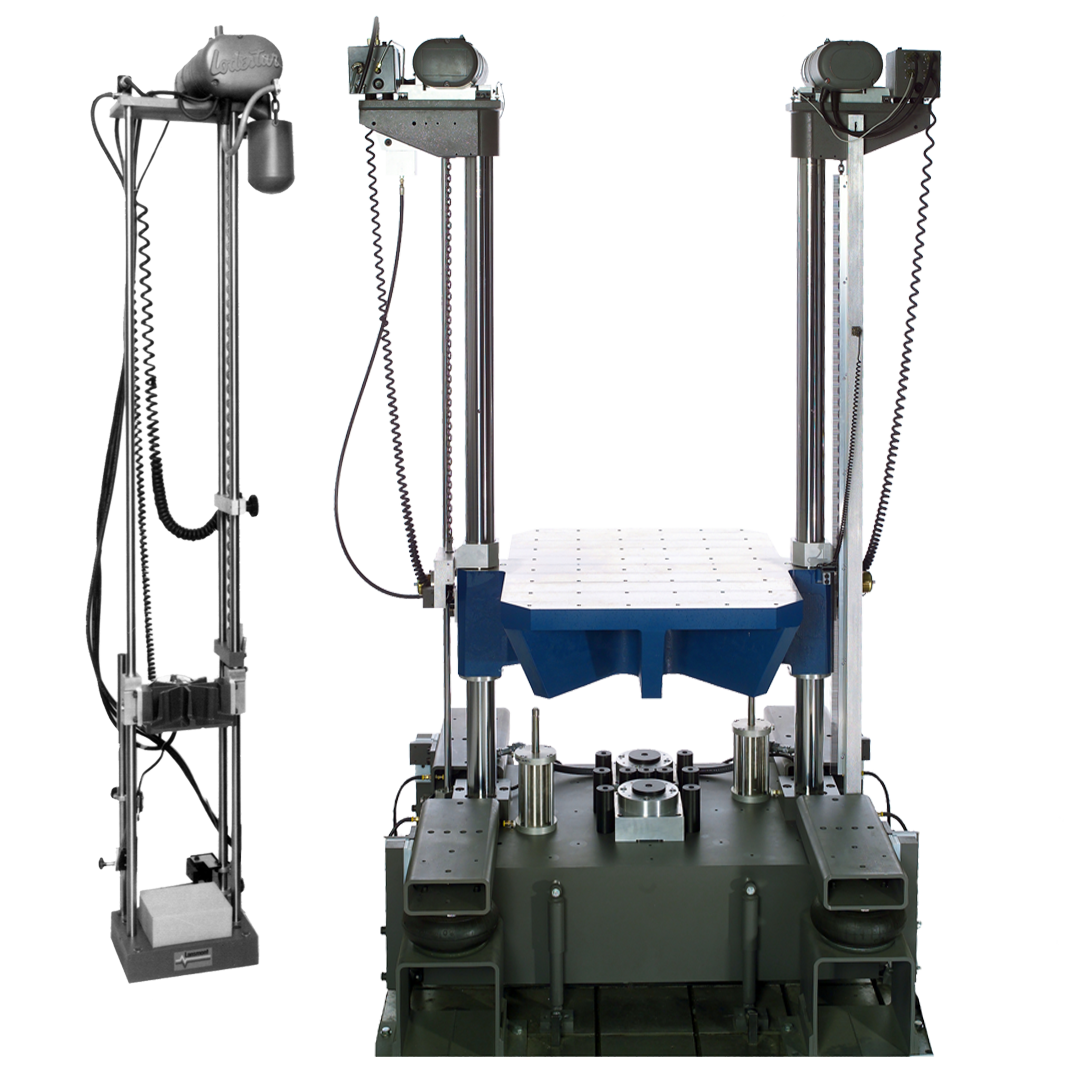

Selection of a shock test system is based on the size and mass of your largest test specimen, as well as the shock performance required. Shock performance criteria includes velocity change and acceleration level. It is also important to know the shock pulse waveforms required, eg half sine, sawtooth or trapezoidal. Our consultative sales process will ensure the perfect fit for your business requirements.

For any mechanical shock testing application, Lansmont build shock test systems to meet your specific requirements.

Lansmont's standard shock test systems include:

- initiation and system level training

- comprehensive one-year warranty on all components

We also offer complete applications training programs to ensure you get the greatest value from your investment.

Brochures

Got a question about this solution?

Get in touch and speak to one of our Technical Sales Engineers now...

Speak to an expert

Test Partner™ Data acquisition and analysis systems

Data acquisition systems are critical for both product and package dynamic testing scenarios.

At Lansmont, our Test Partner shock data acquisition systems recognize the needs of product testers across industries to deliver a capable, high-precision system.