Drop testing determines the ability of a package to withstand the impacts prevalent in the distribution environment.

This process is vital for ensuring that products travel to customers safely and securely, eventually arriving damage free. In turn, drop test systems help companies save money and maintain positive brand-owner reputations by helping to design packaged products that will deliver products with their intended inherent quality intact. Lansmont Drop Test Systems are the gold standard for accurate and repeatable drop testing. Every drop tester we manufacture is factory-tested to ensure it meets flatness-of-drop requirements and exceeds industry specifications.

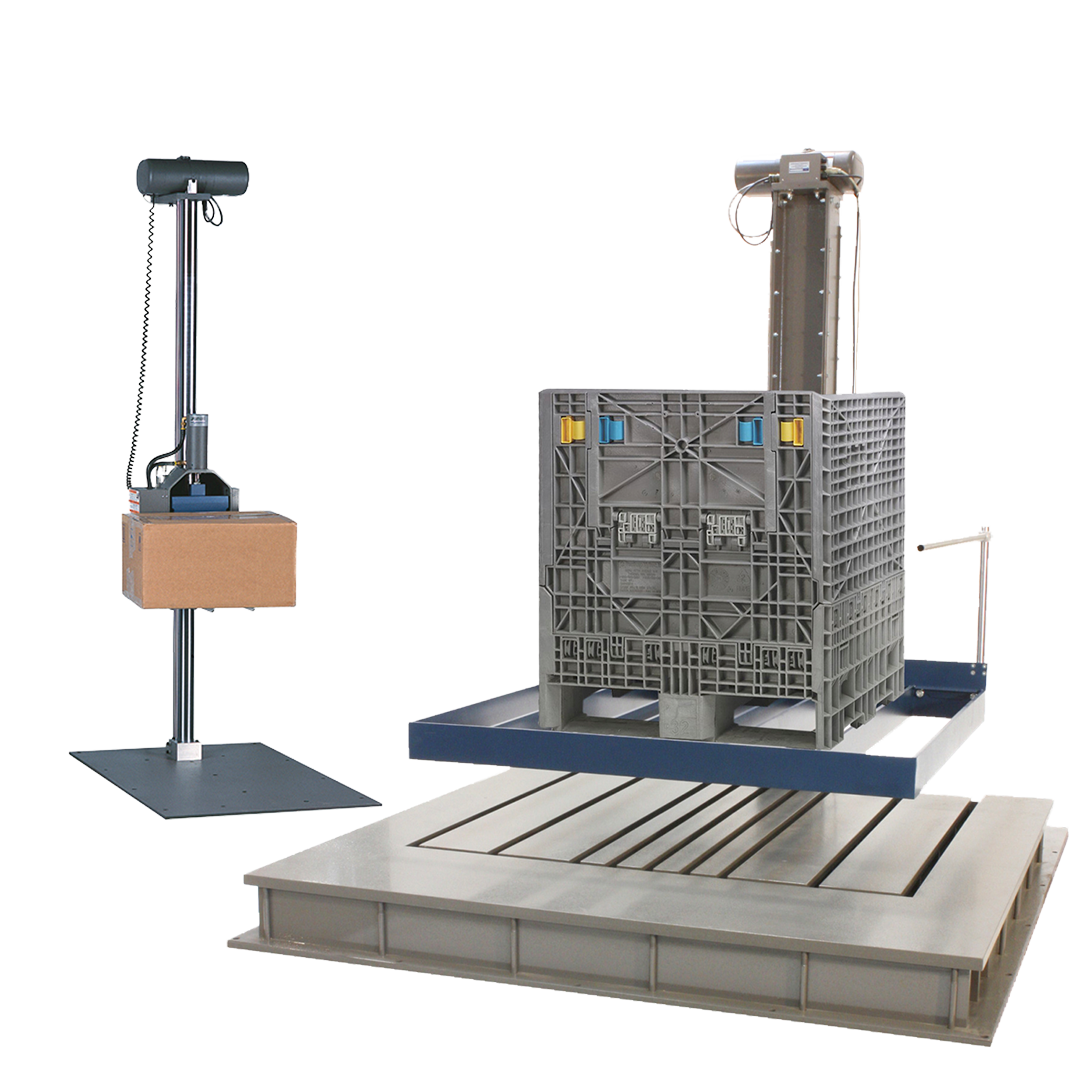

You’ll find various drop testing systems available at Lansmont that you can choose from based on your individualized needs. Each of our solutions offers different configurations, features and handling capabilities suited for shipments of all shapes and sizes.

Brochures

Got a question about this solution?

Get in touch and speak to one of our Technical Sales Engineers now...

Speak to an expert

What is the purpose of drop testing?

Drop testing mimics the shipping and distribution environment in a way that exposes packages to the types of impacts they may endure while traveling through the supply chain. By controlling the height from which the test samples are dropped, users are able to control the impact velocity, which is proportional to impact energy.