Achieving 'flatness of drop' in drop testing

One key consideration for Drop Testers is their ability to deliver “flatness of drop.”

That means if I place a package on a drop tester in an orientation, I want it to impact the floor (or baseplate) on that same orientation - without any change in orientation during the drop or free fall. Flatness of drop is specifically called out within ASTM D5276 (Standard Test Method for Drop Test of Loaded Containers by Free Fall).

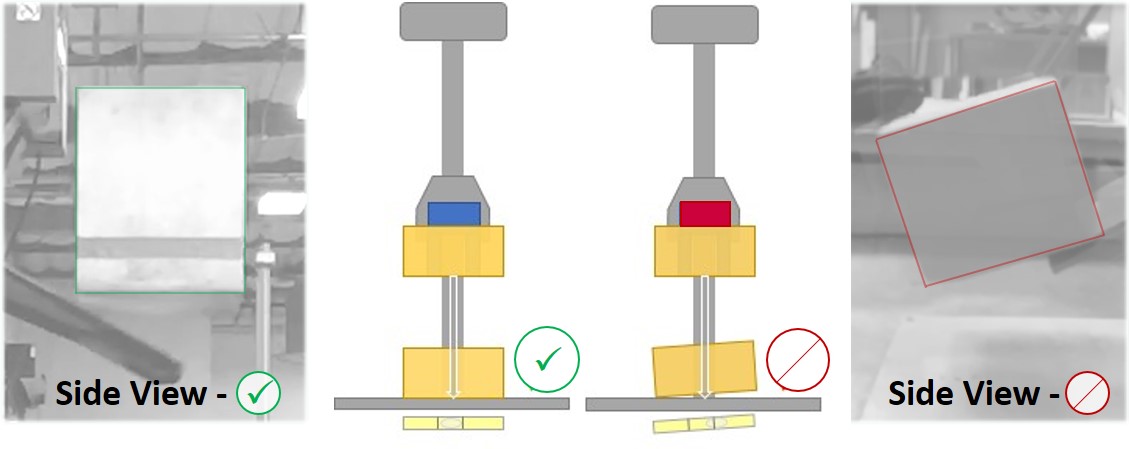

D5276 says in-part "It shall permit the container to be placed, prior to release, in a position that will ensure correct orientation, within 2 degrees upon impact, for flat-face drops..." Below, the left image shows a proper release with no rotation, while the image on the right shows a release with undesired rotation.

If rotation occurs during a drop, the amount of acceleration (Gs) that is transmitted into that package face upon impact is less than it would have been – had it hit perfectly flat. This is because some of the impact energy is now shared between the primary and off impact axes – rather than being totally focused into the primary axis.

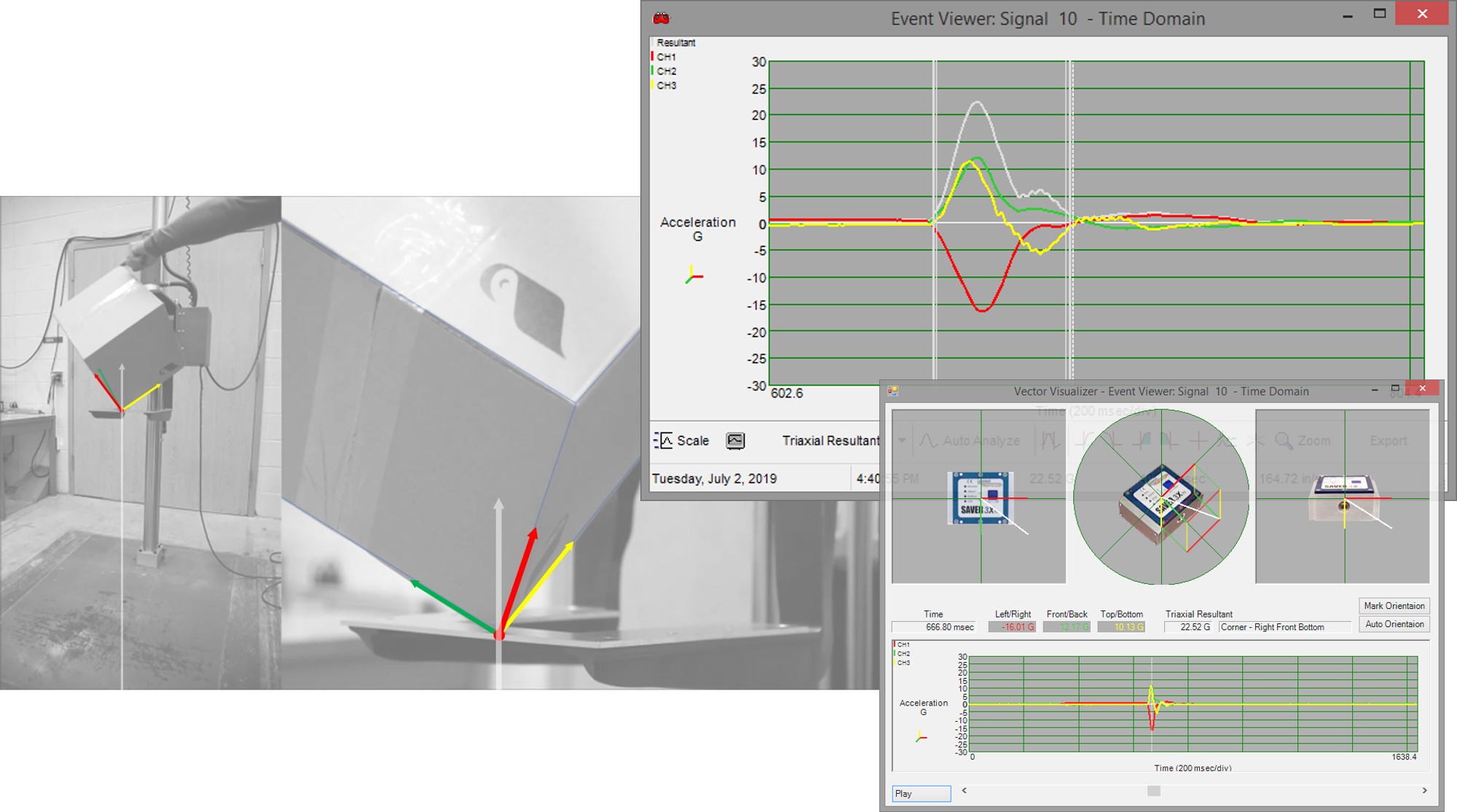

This is demonstrated below with orientation image and impact event graph. The graph shows how the vertical, lateral and longitudinal acceleration is distributed during a non-flat drop (a corner drop). If it were a perfectly flat drop, all the acceleration (Gs) would be shown on just one channel, not all three. The data shown below occurred on the corner of the package, so the resulting acceleration was experienced/measured in all three translational axes - X (red), Y (green) and Z (yellow).

If your product is fragile in any specific orientation, you want to make sure to understand the full acceleration/energy challenge that it may encounter as transmitted through the package. AND - If you or your colleagues later repeat the testing - you want confidence that the testing inputs are the same each time – and not varying because of the flatness of the drop. Repeatable flatness of drops – tuns out - is not as simple as it might seem.

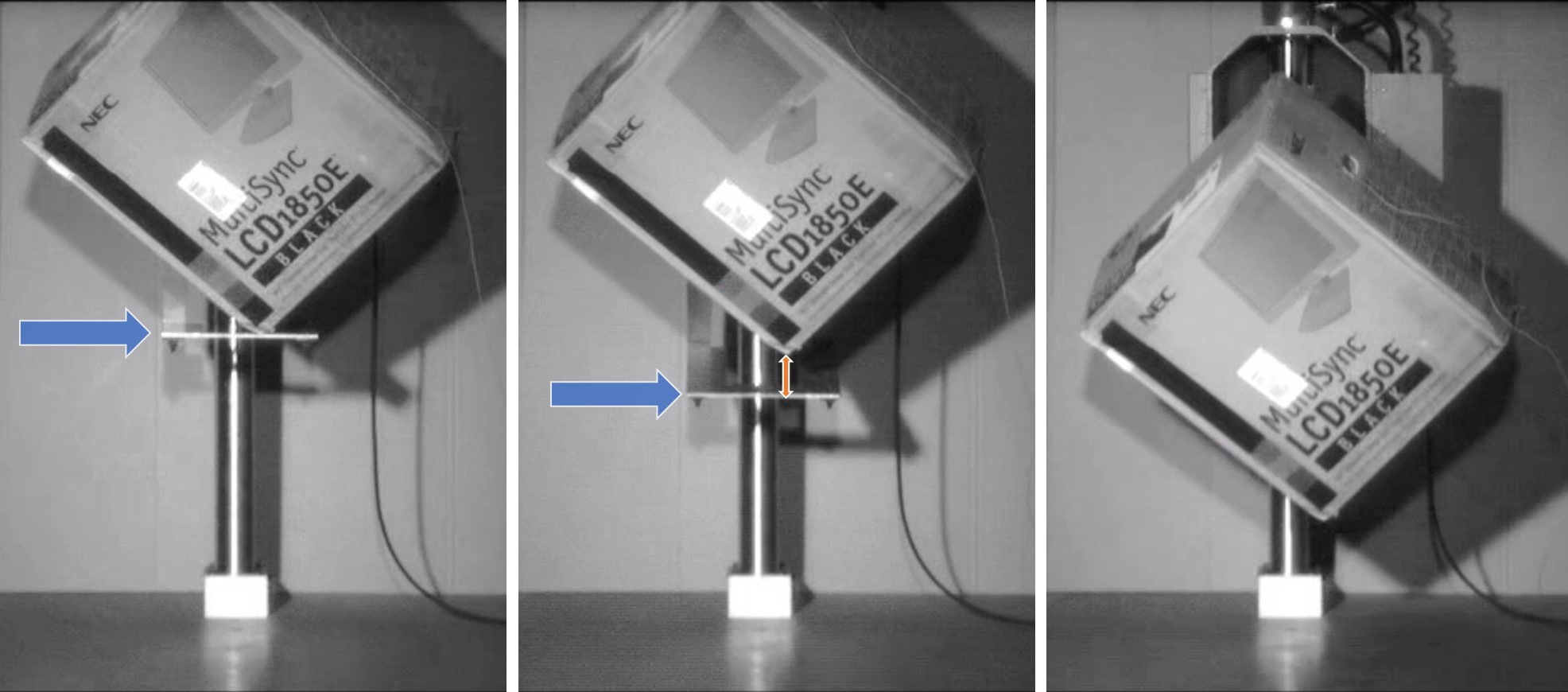

Lansmont Drop Test Systems incorporate a special system to accelerate the drop leaf downward away from the package – faster than gravity – effectively leaving the package hanging in mid-air. Once out of contact with the package – the system rotates the drop leaf away to allow the package a clear free-fall line. This entire process occurs at a rate faster than gravity – allowing for immediate and complete separation from the test item/package, and then undisturbed free fall.

Flatness of drop demonstration

You can download individual Drop tester product specification datasheets from lansmont.com/support